Description

The Ultimate Manufacturing System — at an Unmatched Price

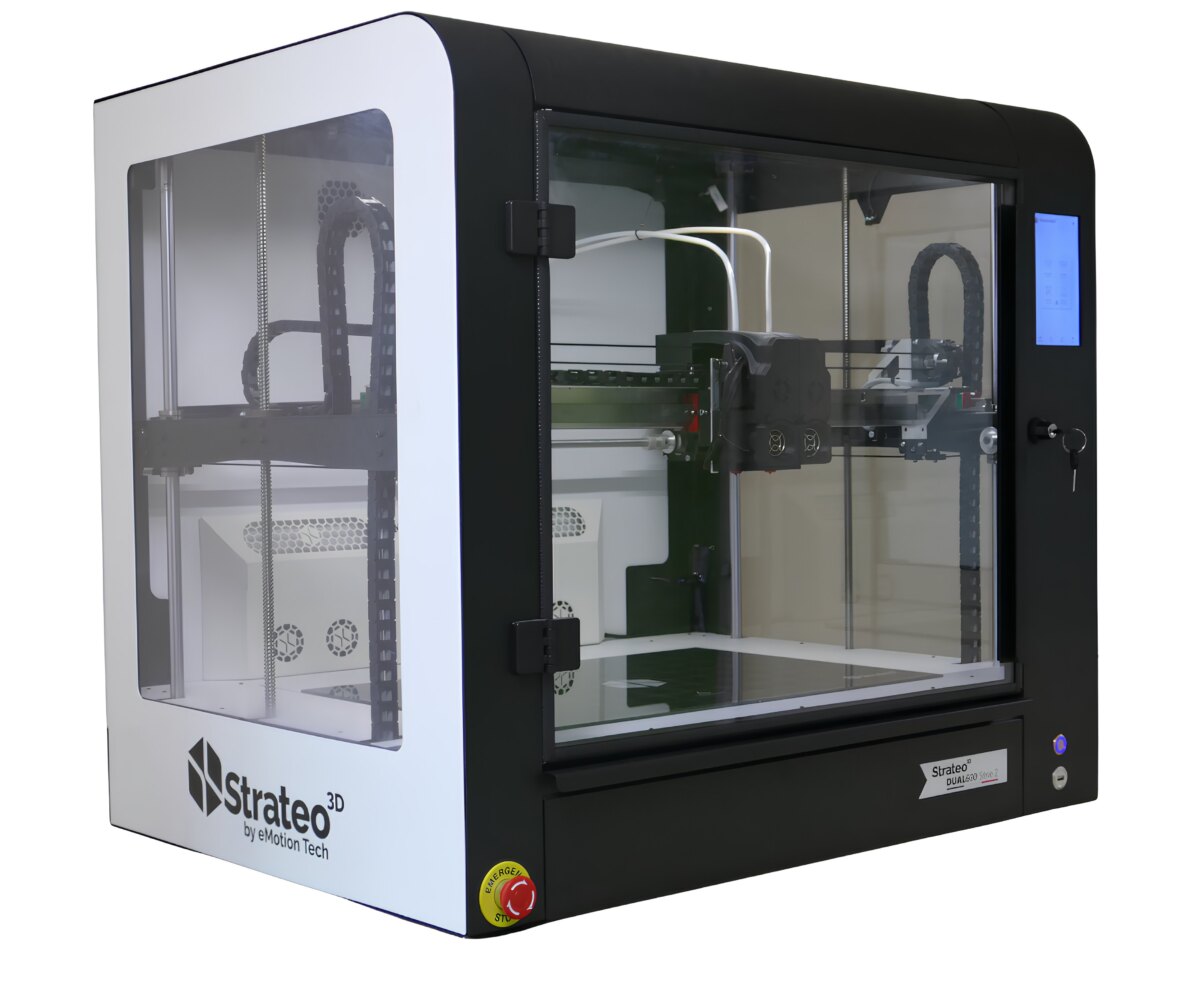

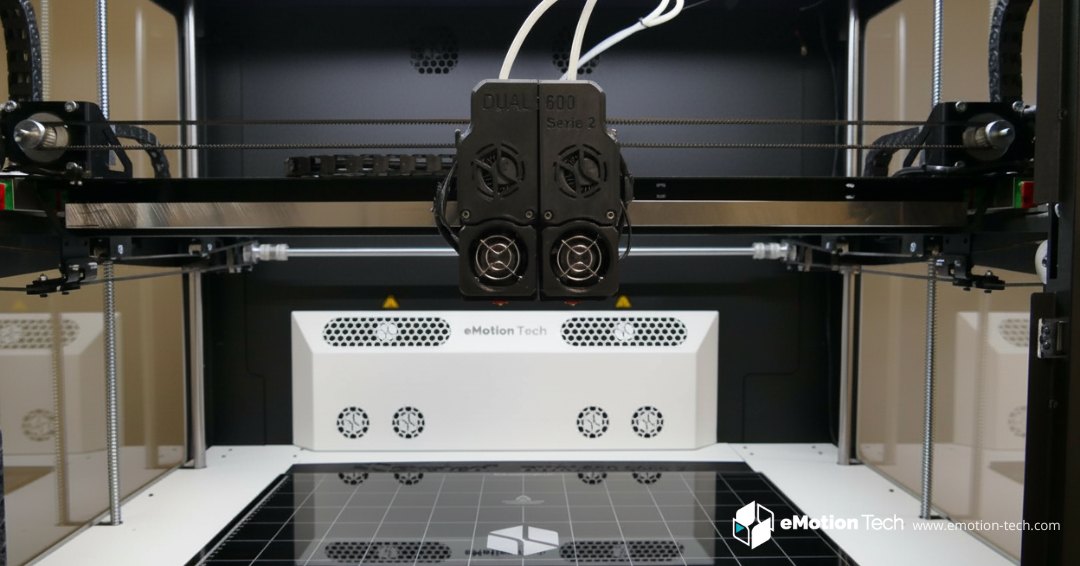

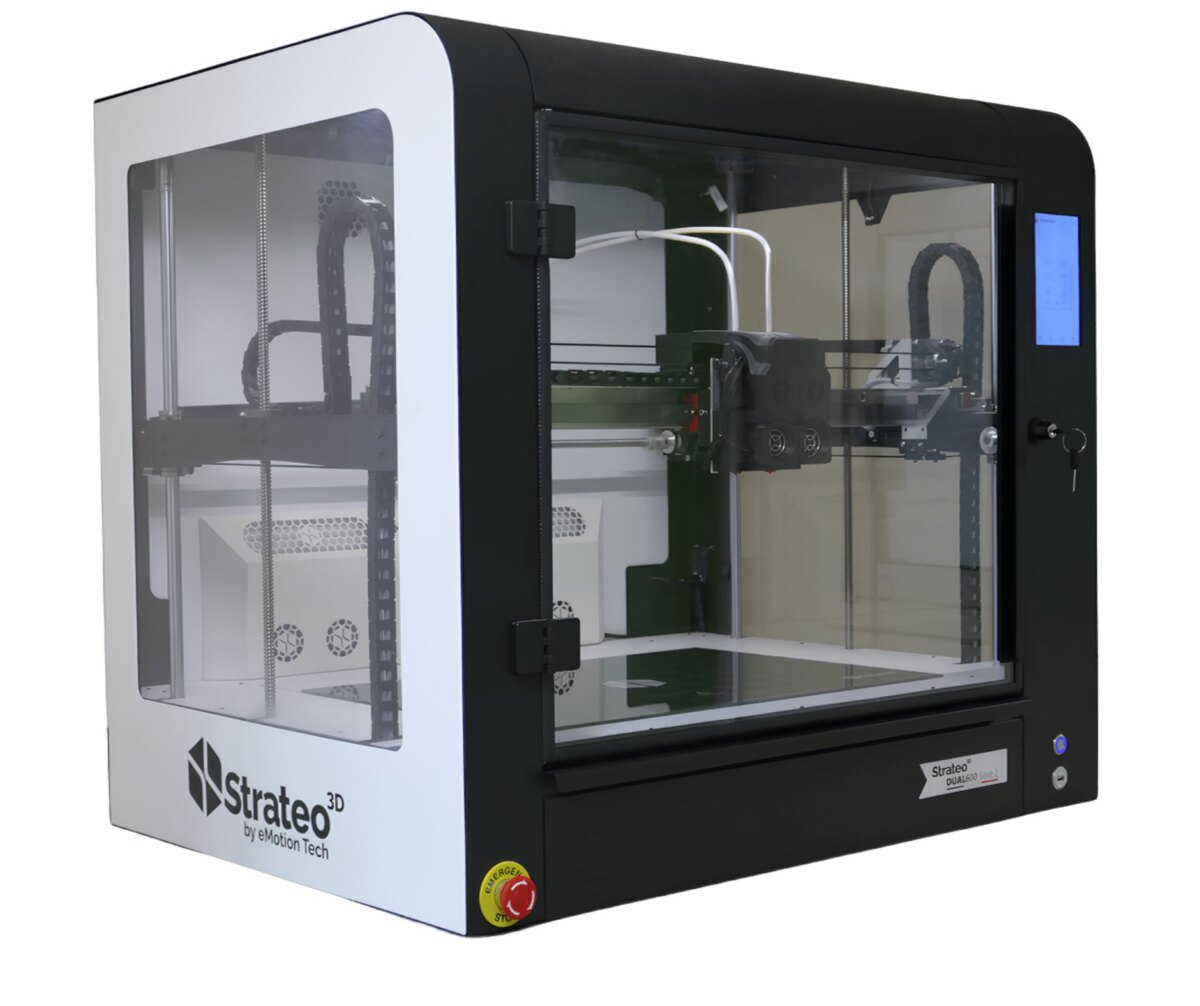

The Strateo3D Dual 600 is a high-performance industrial 3D printing system engineered for serious production environments. Built on advanced FDM technology, the Dual 600 delivers exceptional reliability, precision, and material versatility for demanding manufacturing applications.

With standard extrusion temperatures reaching 300 °C, and up to 400 °C when equipped with the optional high-temperature toolhead, the Dual 600 enables the production of robust, end-use parts and functional prototypes. This expanded thermal capability allows you to work with a wide range of engineering and high-performance materials, including PEKK, ASA-X, and Acetate, among many others.

Designed for scalability and efficiency, the Dual 600 is ideal for industrial prototyping, tooling, jigs and fixtures, and low-to-medium volume production. Explore the datasheets below to discover detailed specifications, material compatibility, and real-world use cases.

| Dimensions | H 850mm, W 950mm, Depth 720mm |

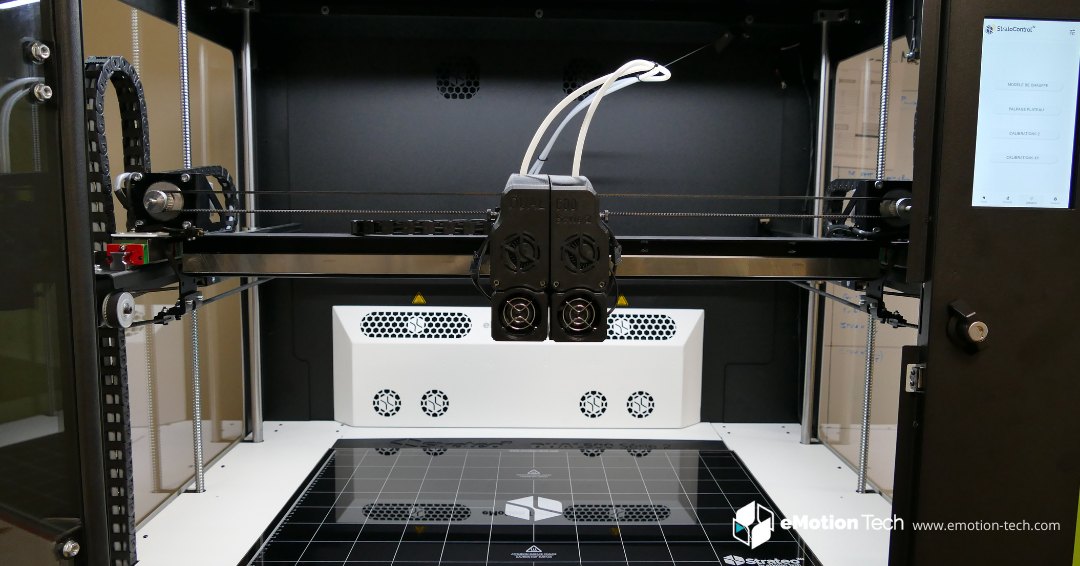

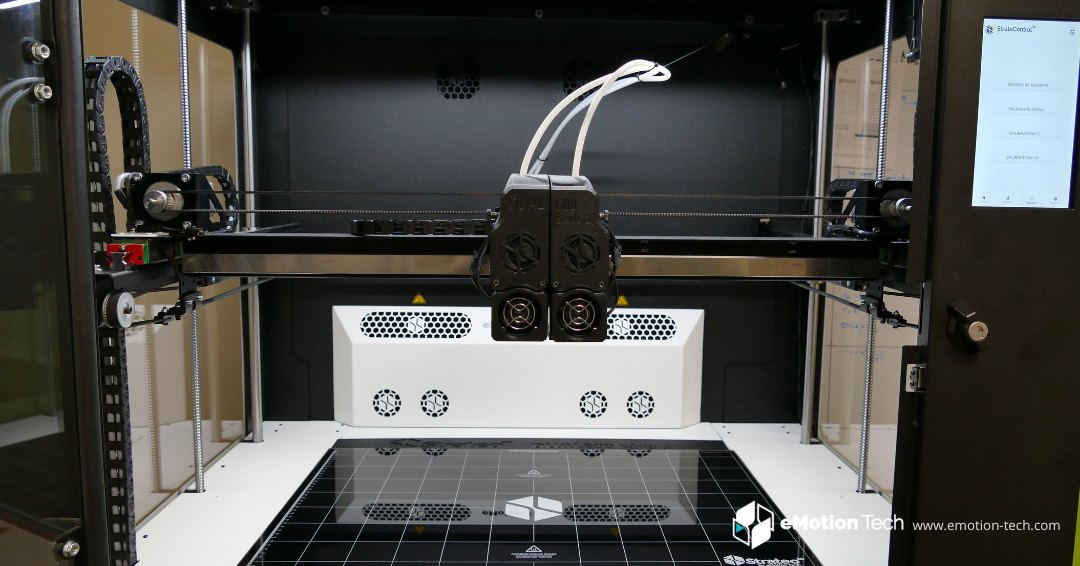

| Printing volume | 500 * 600 * 420 (126L) |

| Compatible filaments | All non-proprietary materials available in 1.75mm format: PLA, ABS, PETG, TPU, HIPS, PVA, BVOH, PA 6-66, PC, ASA, Acetate, PEKK (high-temperature tool required) |

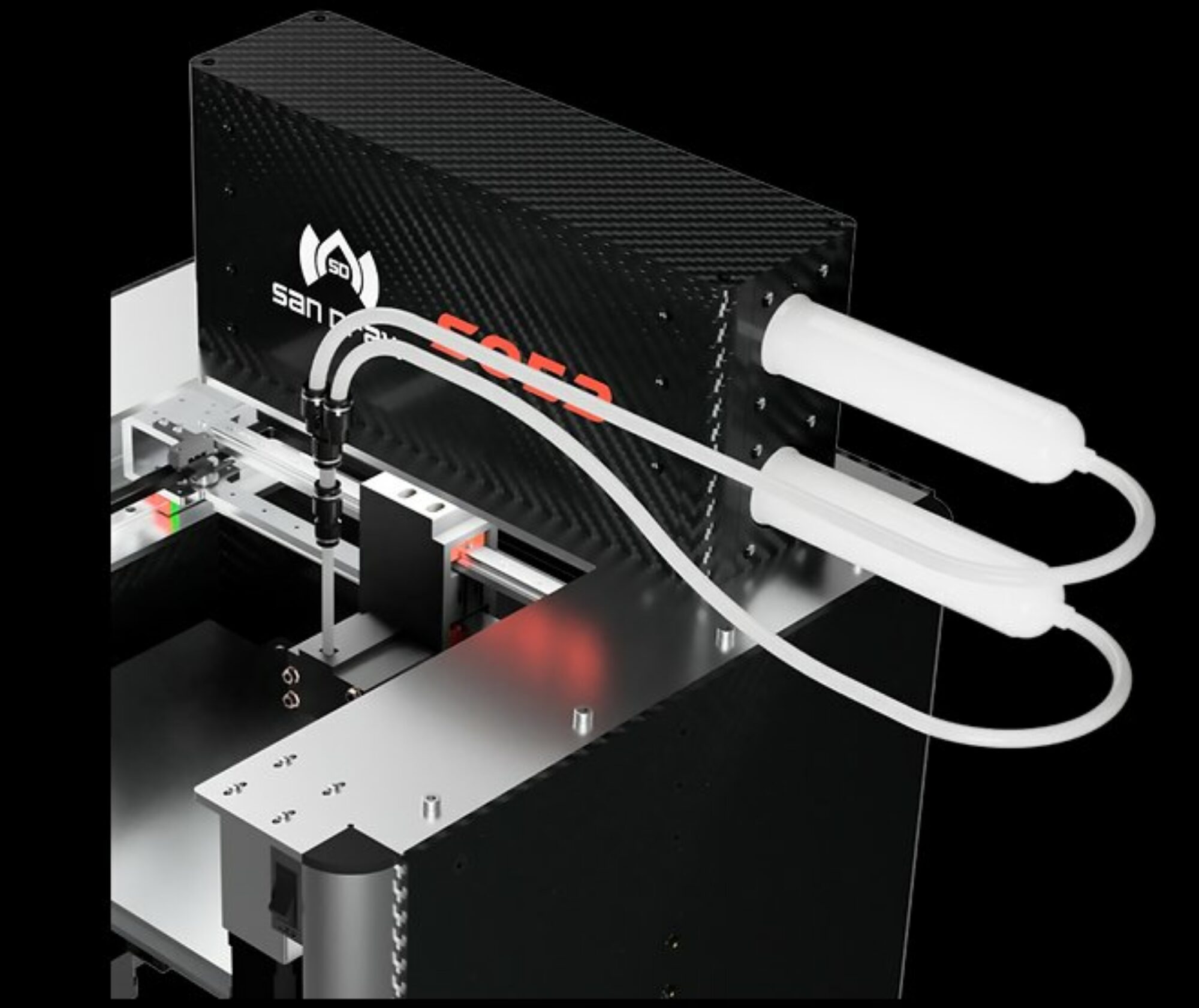

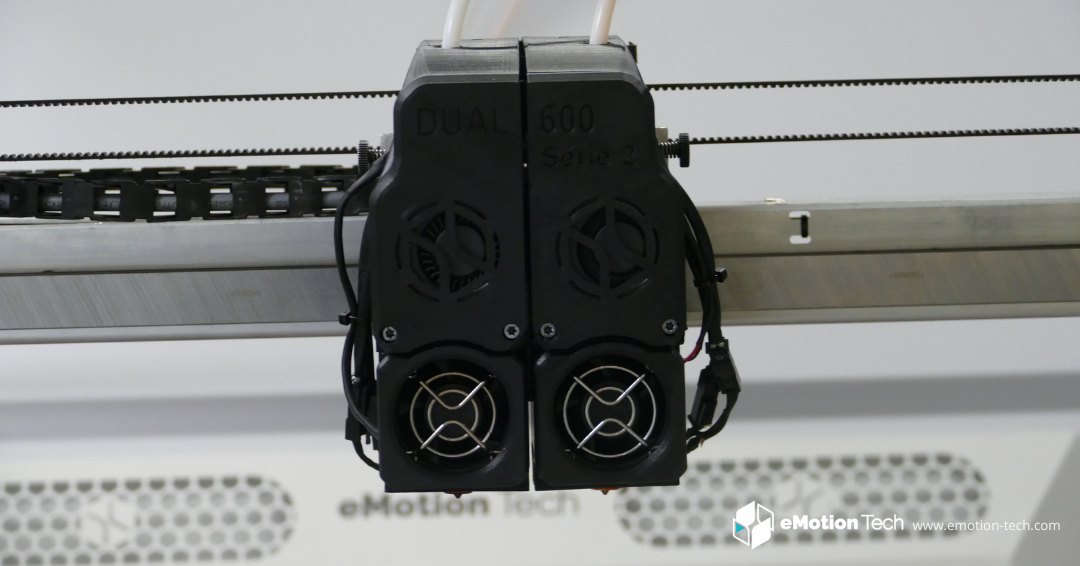

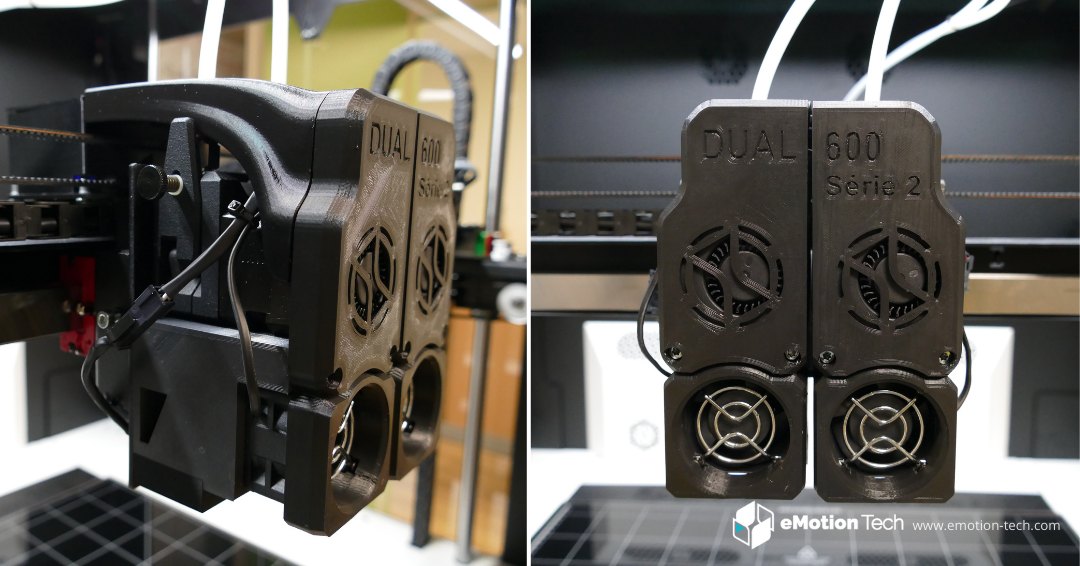

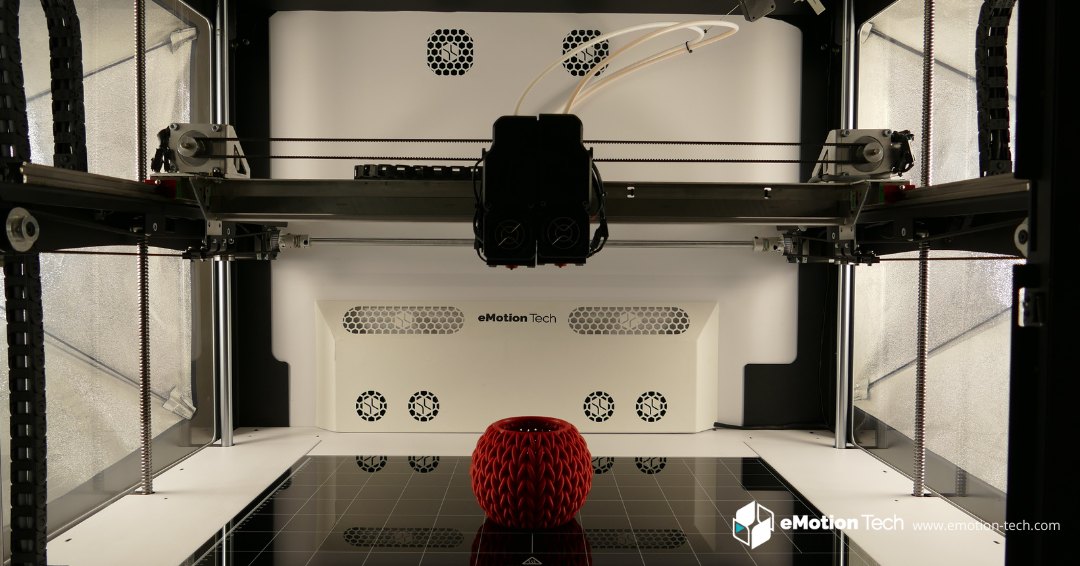

| Extrusion | 2 independent extruders, 2 material or 2 color |

| Nozzle diameters | 0.25 to 1.2mm |

| Extrusion temperature | Up to 500°C |

| Printing surface | Up to 140°C |

| Working volume | Up to 70°C |

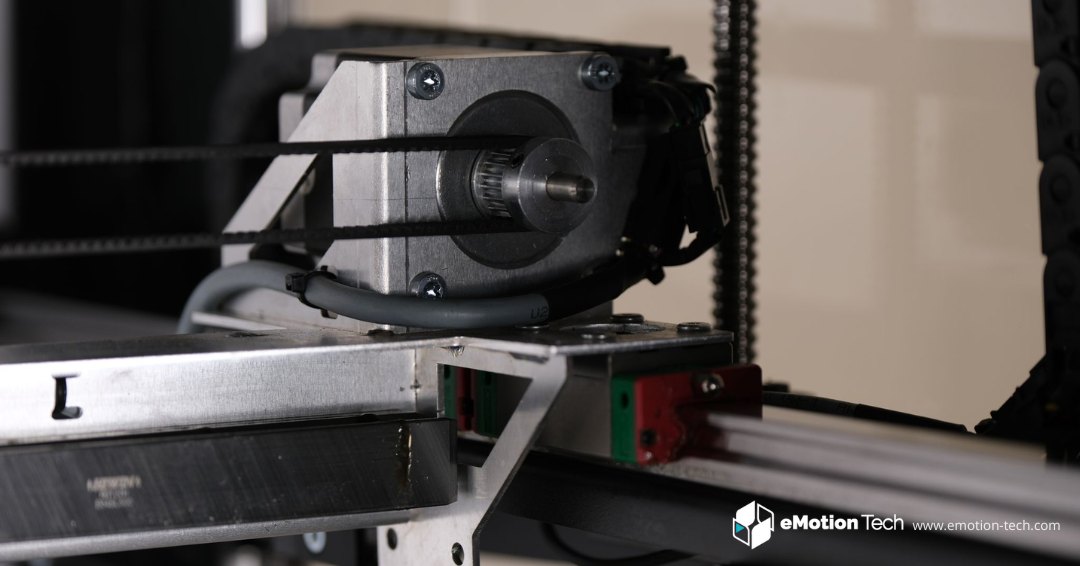

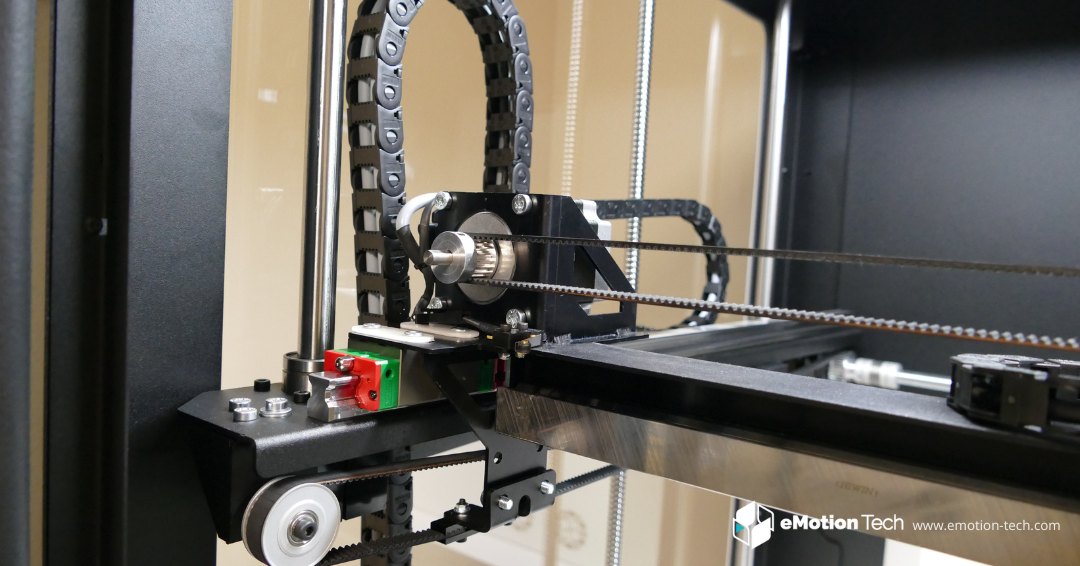

| Motion accuracy | XY axis : 5µm / Z axis : 3µm |

| Filtration | Classic HEPA and active carbon |

| Software | Stratocontrol3D by eMotion Tech |

| Connectivity | USB, ETHERNET |

| Supported operating systems | Mac OS, Windows, Linux, Android, iOS, and any system with a web browser. |