Description

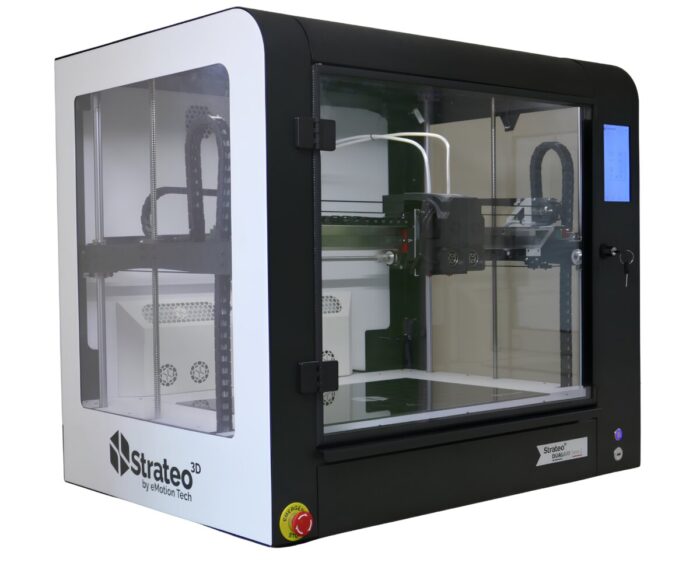

Direct Annealing System

The Direct Annealing System (DAS) is the world’s first and exceptional technology created by CreatBot. The annealing process can already be controlled during the printing process. This technology produces high-quality, large-scale parts. The printing process is seamless, and when building large-scale parts, there is no warping or cracking of the model during printing.

Ultra high-temperature nozzle, printing bed, and hot chamber

The CreatBot PEEK-300 3D printer has an ultra-high temperature nozzle. It heats up to 500°C. Therefore, the prints are reliable, outstanding and you will be able to use a wide range of materials.

In addition, the printing bed will heat up to 200°C, which is an ordinary but necessary foundation for printing large-scale models without warping.

The hot chambers temperature is 120°C, to create excellent prints and protects the prints from cracking during the printing process.

Triple Heat Isolation

Another feature is the triple thermal insulation. This one is made of a double insulating chamber, advanced insulating materials, and vacuum double PC panels. Safety and maximum performance are thus guaranteed.

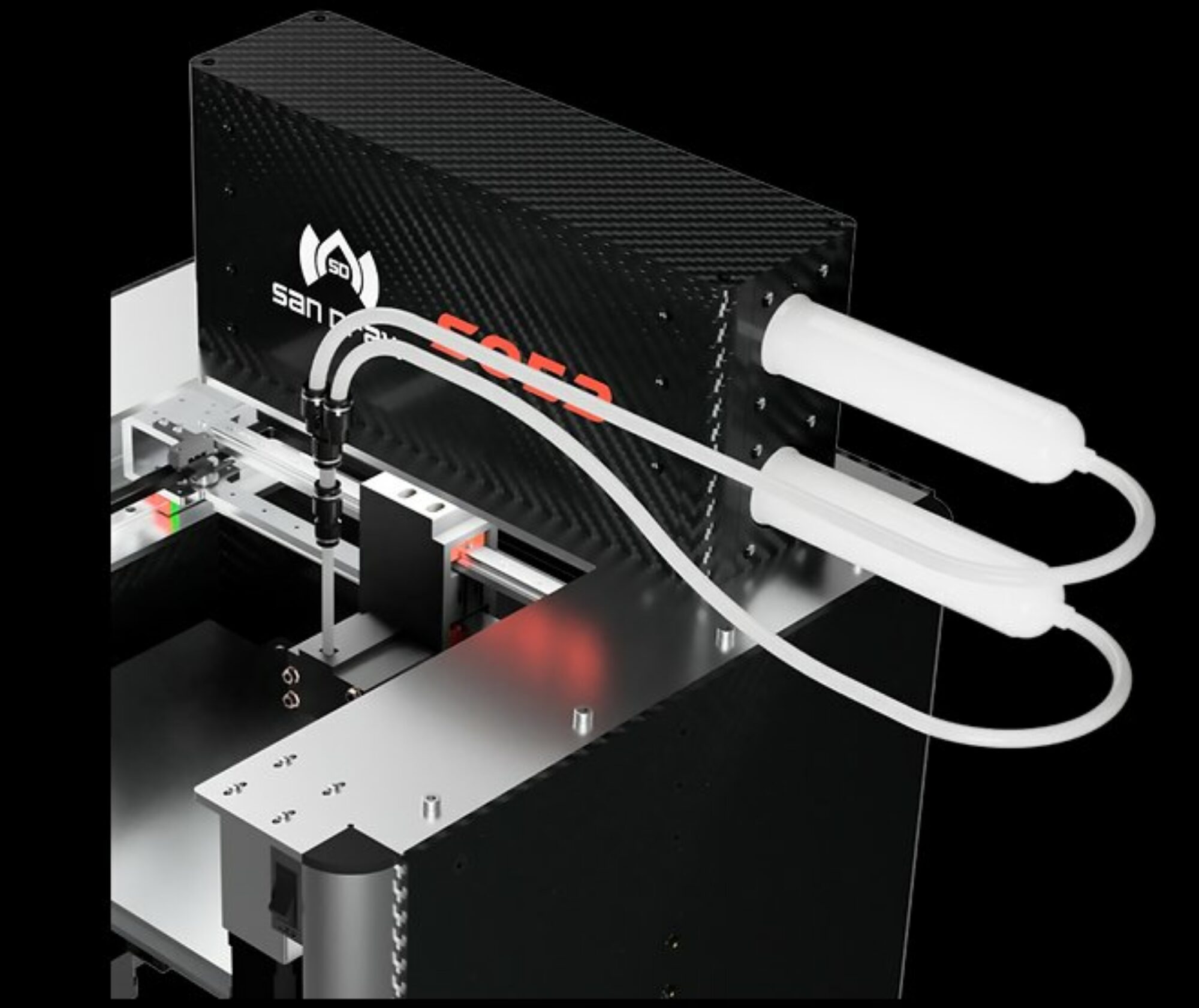

Cooling System

One of the most essential components of the entire thermal system of the CreatBot PEEK-300 is the cooling system.

The cooling system is made up of two components.

The first is the liquid cooling system. The circulating liquid can be used effectively for a long time.

The second component is the air pump cooling system. Here the air pump uses cold air from outside instead of the hot air in the chamber.

Ultra-High Resolution – 0.04 mm

Even though 0.04 mm is an available resolution for standard plastics, this is an exceptional resolution for high warpage and deformation materials.

This is important because 3D printing high-performance materials require not only high temperature but also better cooling. For high resolution with lots of small details, high temperature will ruin the layers into a mess if heat and cooling are not in balance.

All this is given with the CreatBot PEEK-300.

Don’t forget to have a look at our other products HERE

Specifications

- Build Volume: 300 x 300 x 400mm

- Print Resolution: 0.04mm-0.4mm

- Filament Diameter:1.75mm

- Number of Nozzles: Dual Extruder

- Print Speed: 10-150mm/s

- Nozzle Diameter: 0.4mm (0.3~1.0mm optional)

- Filament Compatibility:

- Engineering Plastics: PLA, TPU, PC, ABS, PA6, PETG, PVDF, TPU

- High temperature Material: PPSU, PEI (ULTEM), PA12, PSU, PPS, PA-CF, POM, PP

- Ultra-performance material: Medical grade PEEK, PEEK, PEKK, CF-PEEK (Carbon fiber), GF-PEEK (glass fiber), etc.

- Nozzle Max. Temperature: 500℃

- Chamber Temperature: 120℃

- Platform Max. Temperature: 200℃

- Direct Annealing Temperature: 0~400℃

- Software Bundle: Creatware, Simplify3D, Cura, Slice3r

- Operating Systems: Win7/8/10

- Print File Type: STL, OBJ, AMF, Gcode

- Cooling: Air pump cooling & water cooling

- Platform: PCB aluminum + PEEK print board

- Positioning Precision: X Y axis 0.01mm, Z axis 0.0025mm

- Extruder: Directly Drive

- Machine Construction: Fully enclosed hot chamber

- Bed Leveling: Manually/Automatic

- Outage Restored: Save data when power is off

- Filament Detection: Pause printing when filament run out

- Direct Annealing System (DAS)

- Heat insulation: Triple heat insulation

- Emergency stop switch: Support emergency stop

- High temperature accessories: High temperature resistance motors, linear rails, belts and circuits to ensure long time high temperature printing

- Input Power: 200V~240V, 20A

- Rated Power: 4600W

- Screen: 4.3” full color touch screen, multi-language

- Print Method: USB Connectivity/USB Disk

- Machine Size: 650 x 600 x 750 mm

- Weight: 100 kg

- Packing Size: 820 x 720 x 1080mm

- Packaging Weight: 130 kg