Description

AI-S1200 Signage 3D Printer

Precision, Power, and Performance for Large-Format Signage Fabrication

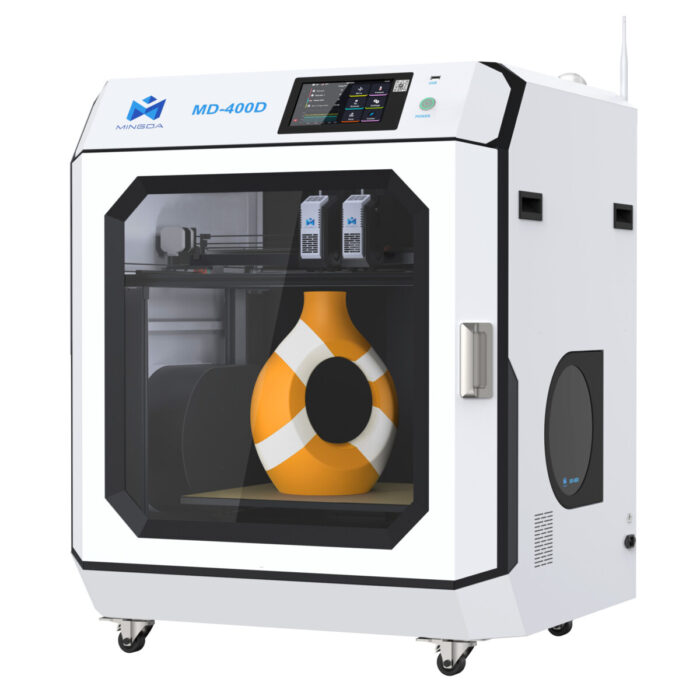

The AI-S1200 Signage 3D Printer is purpose-built for professionals who demand accuracy, scale, and efficiency in LED signage production and complex 3D modeling. With a massive 1200 × 1200 × 100 mm build volume, this printer empowers creators to fabricate full-sized sign components or intricate multi-part designs in one seamless print.

Key Features

-

Large-Format Build Area:

Achieve expansive prints with a 1200 × 1200 × 100 mm workspace—ideal for oversized signage letters, branding displays, and custom architectural elements. -

High-Speed Printing:

Print at speeds of 100–300 mm/s with Klipper firmware optimization, ensuring smooth, stable motion and rapid production cycles. -

Precision Temperature Control:

-

Nozzle Temperature: 180 – 300 °C

-

Heated Bed: 60 – 120 °C

These ranges support a wide variety of engineering and signage materials with excellent layer adhesion and surface finish.

-

-

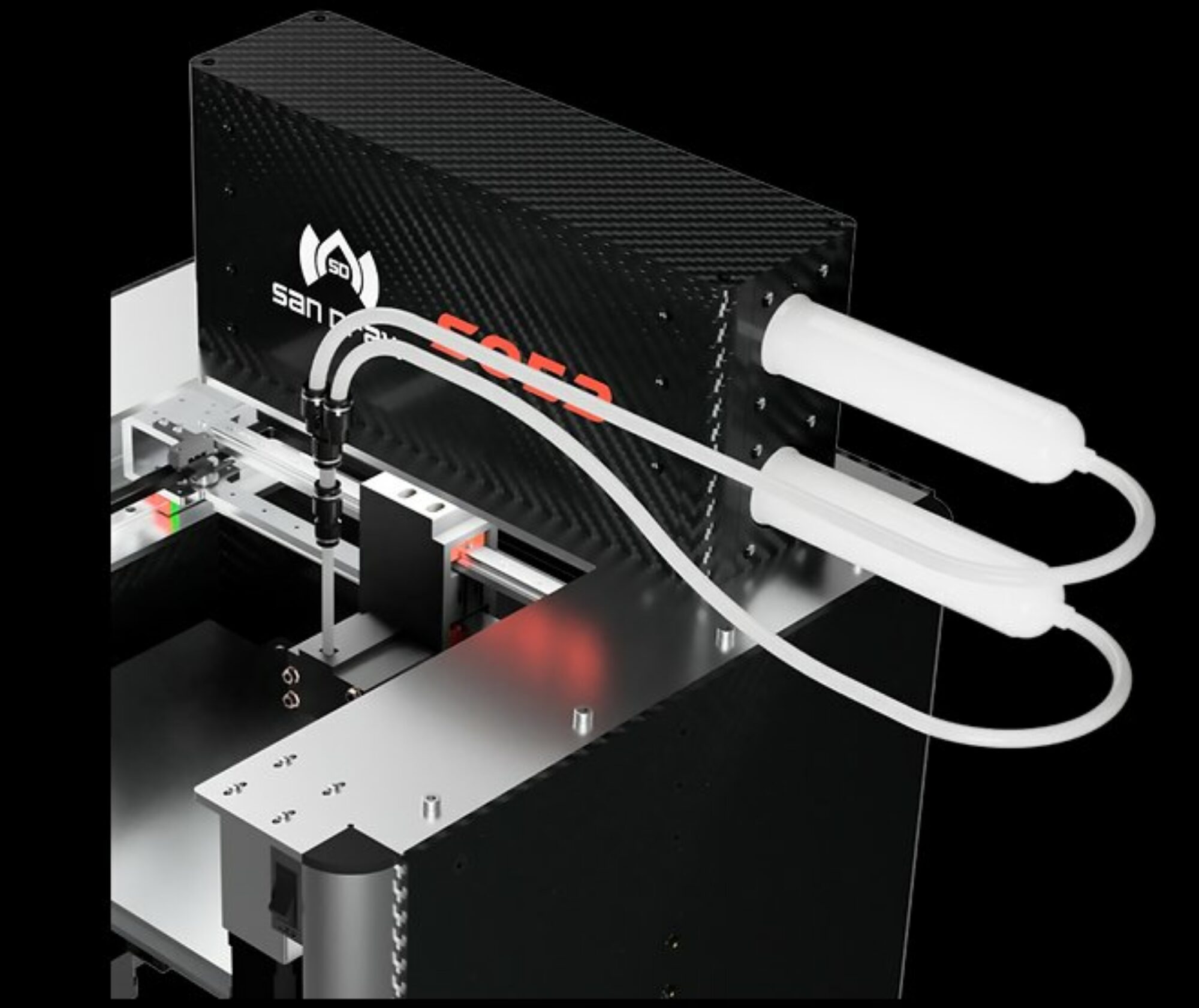

Moisture-Proof Filament System:

Integrated filament moisture-proof box ensures material stability, preventing degradation and guaranteeing consistent extrusion quality. -

Compatible Filaments:

Designed to support MMLA, AD-PETG, PDS, and PLA, providing flexibility for different signage applications, from durable outdoor use to fine indoor displays. -

Smart Control with Klipper Firmware:

Experience next-level speed tuning, real-time monitoring, and seamless multi-axis coordination—all managed through the robust Klipper firmware system. -

Universal Power Support:

Compatible with both 110V and 220V power inputs for global usability. -

Minimum Order Quantity:

1 PC – making it accessible for both small businesses and large-scale manufacturers.

Applications

-

LED channel letter and signage production

-

Complex model prototyping

-

Architectural models and decorative structures

-

Industrial design mockups and large-scale 3D parts

AI-S1200 delivers industrial-grade results with the simplicity and precision needed for modern signage manufacturing—bridging the gap between creativity and production efficiency.