Description

Liqcreate Clear Impact SLA and DLP 3D Printing Resin

Liqcreate Clear Impact is a durable and easy to print stereolithography (SLA) and Digital Light Processing (DLP) material that is optically clear, slightly flexible, and has excellent impact resistance. It is ideal for the production of functional parts which are repeatedly exposed to stress, such as jigs, fixtures, and tooling. Liqcreate Clear Impact also has low water absorption and weather resistance, making it perfect for outdoor applications.

Key features:

- Optically clear

- Excellent impact resistance

- Good water and chemical resistance

- Low yellowing

- Easy to print

- Compatible with a wide range of SLA and DLP 3D printers

Applications:

- Functional prototypes

- End-use parts

- Jigs and fixtures

- Tooling

- Outdoor applications

- Display applications

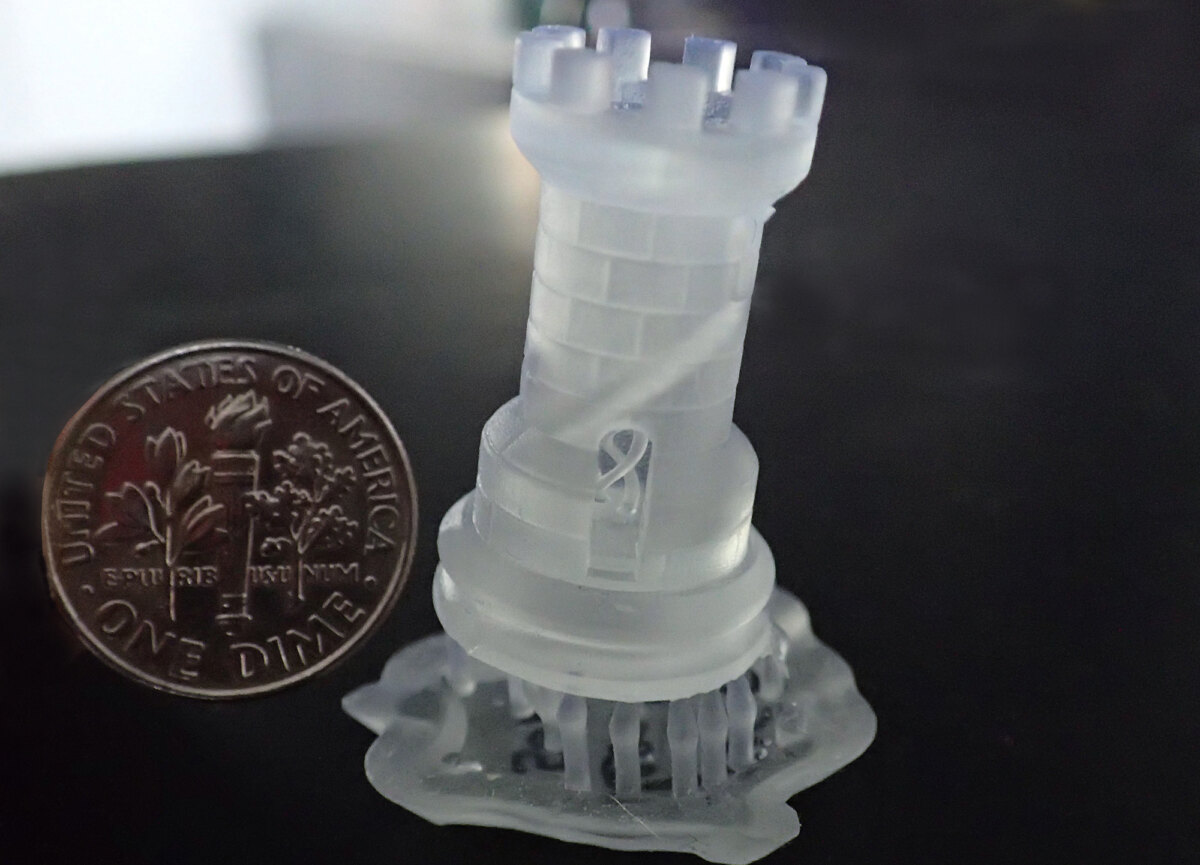

Examples:

- Clear housings for electronic devices

- Lenses and optical components

- Prototypes for automotive and aerospace parts

- Outdoor signage and displays

- Medical and dental devices

3D printer compatibility:

- Moonray S & D

- Miicraft 125

- Form2

- Peopoly Moai

- Asiga Max and 4K

- Anycubic & Elegoo series

- All open 385 – 405nm SLA, DLP and monochrome MSLA 3D-printers

How to use:

- Shake the bottle well before use.

- Pour the resin into the resin vat of your 3D printer.

- Level the build platform.

- Slice your 3D model and send it to the printer.

- Print your model according to the manufacturer’s instructions.

- Once the print is finished, remove the part from the build platform and wash it in isopropyl alcohol (IPA) to remove any uncured resin.

- Post-cure the part under a UV lamp for 30 minutes.

Tips:

- For best results, use a clean and level build platform.

- Use a resin filter to remove any impurities from the resin.

- Store the resin in a cool, dark place.

Storage:

Store the resin in a cool, dark place at temperatures between 15 and 30 degrees Celsius. Avoid storing the resin in direct sunlight or in areas with high humidity.